Products

High frequency induction heating machine high frequency hot circle plastic high frequency induction welding machine metal implanting machine

Five Advantages Of Products

- High frequency heater features, the most simple equipment, lightweight, easy to maintain

- Manual control, automatic control

- Easy to change the mold: the induction coil can be changed freely and can be made into various shapes

- Under water protection, over water temperature protection

- Easy to operate, can learn in a few minutes

Product Details

Machine features:

Basic working principle of high frequency heater:

High frequency and high current flow to a heating coil (usually made of copper tube) which is wound into a ring or other shape

As a result, a strong magnetic beam with instantaneous polarity change is generated in the coil, and the heated material such as metal is placed in the coil, and the magnetic field changes rapidly

The beam will pass through the whole heated material and produce a large amount of

Eddy current, due to the resistance in the heated material produces Joule heat, which makes the temperature of the material itself rise rapidly

It's the principle of induction heating

1. Features of high frequency heater: the equipment is the most simple, light and easy to maintain;

2. Manual control and automatic control;

3. Overload, over-current and over-voltage protection;

4. Under water protection, over water temperature protection;

5. Compared with SCR power, the power consumption of this machine is only half, but the heating speed is the same;

6. Easy to change the mold: the induction coil can be changed freely and can be made into various shapes;

7. The operation is simple and can be learned in a few minutes;

8. Installation is simple, only need to connect electricity and water can use, no need to install, no oil, smoke, ash, gas or explosion

Pay attention to environmental protection.

Application range:

Heat treatment: local or whole quenching, annealing, tempering and diathermy of various metals; hot forming: whole piece forging, local forging, hot heading and hot rolling;

Welding: brazing of various metal products, welding of various cutting tools, saw blade sawtooth, steel pipe and copper pipe, welding of the same and different metals;

Metal smelting: vacuum melting, casting and evaporation coating of gold, silver, copper, iron, aluminum and other metals;

Other applications: semiconductor single crystal growth, thermal matching, bottle mouth heat sealing, toothpaste skin heat sealing, powder coating, metal implanted plastic, etc.

China Dongguan Jiayi ultrasonic Co., Ltd

Contact Person: Ann

Department: Marketing Department

Post: manager

Telephone: +86 13686680469

Landline: +86 0769-85198246

Company Address: Beizha Industrial Zone, Humen Town, Dongguan City, Guangdong Province,China

Factory Address: Beizha Industrial Zone, Humen Town, Dongguan City, Guangdong Province

Website: www.meretel.com

Previous: Ultrasonic fuse

-

Dongguan Dingyi ultrasonic Co., Ltd

-

High frequency induction heating machine high frequency hot circle plastic high frequency induction welding machine metal implanting machine

-

Ultrasonic fuse

-

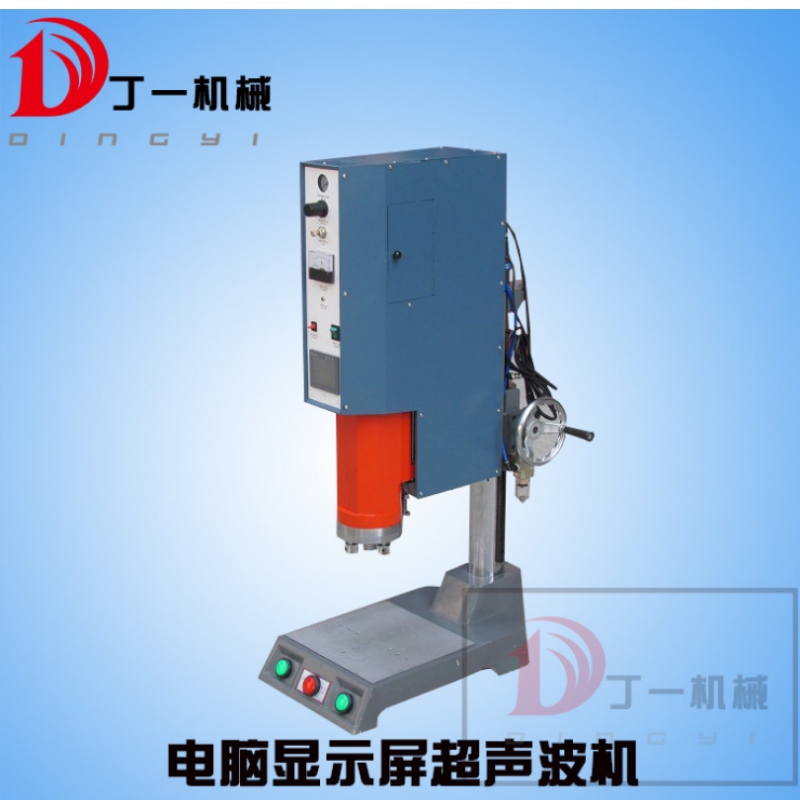

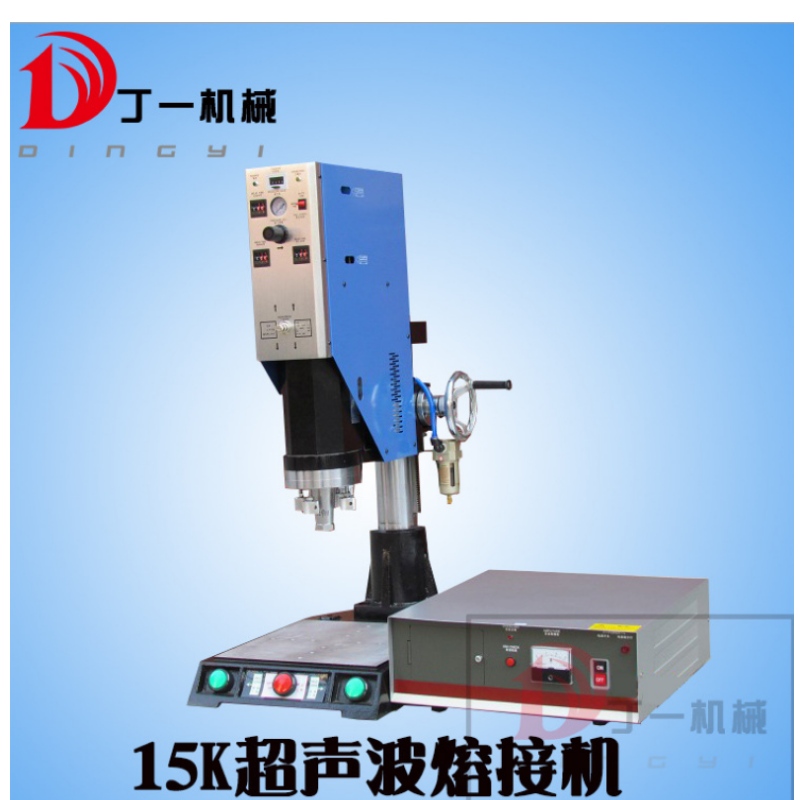

Ultrasonic welding equipment high power ultrasonic welding machine 3200W ultrasonic

-

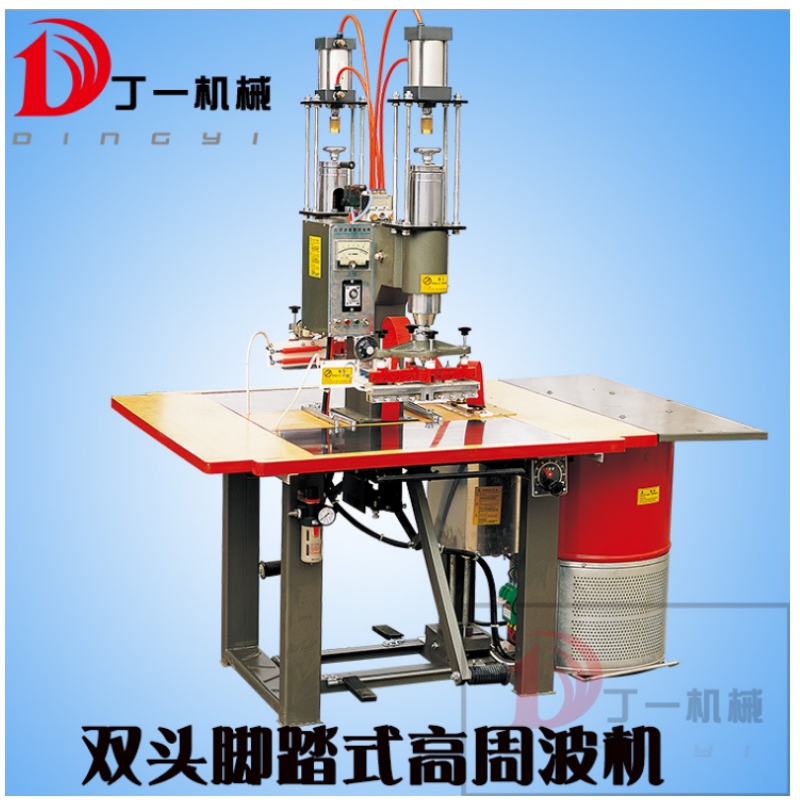

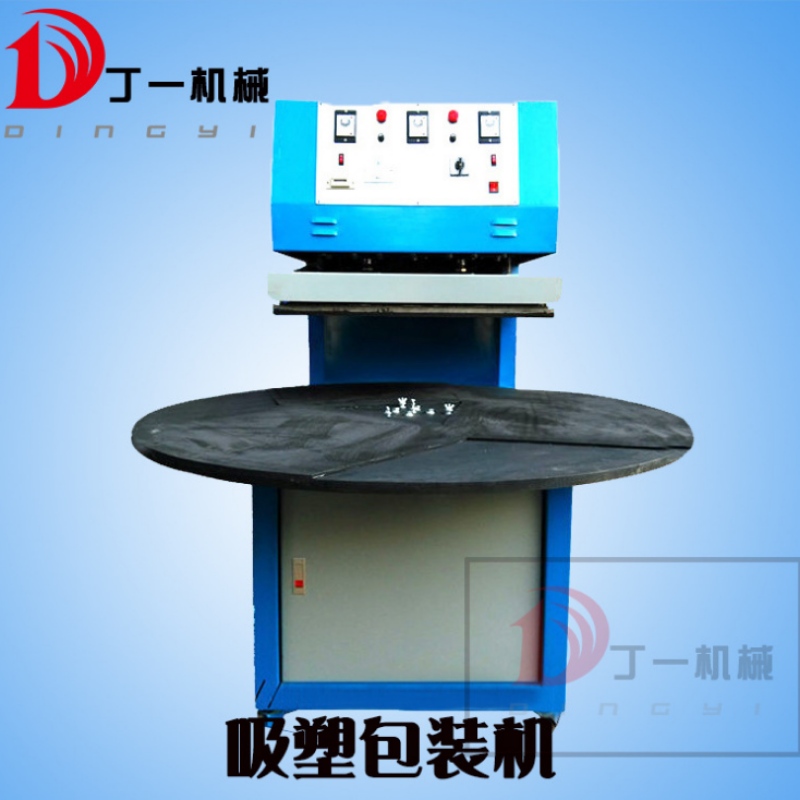

Paper card blister of blister packaging machine

-

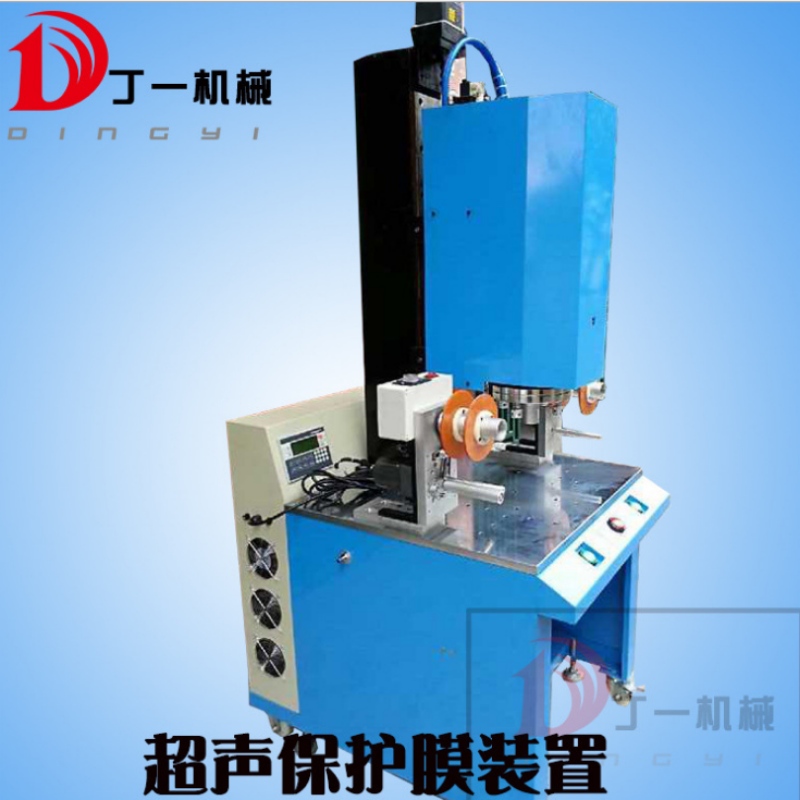

Ultrasonic rotary melting machine plastic welding friction welding machine

-

Charger DC power supply ultrasonic machine ultrasonic welding machine ultrasonic wave

-

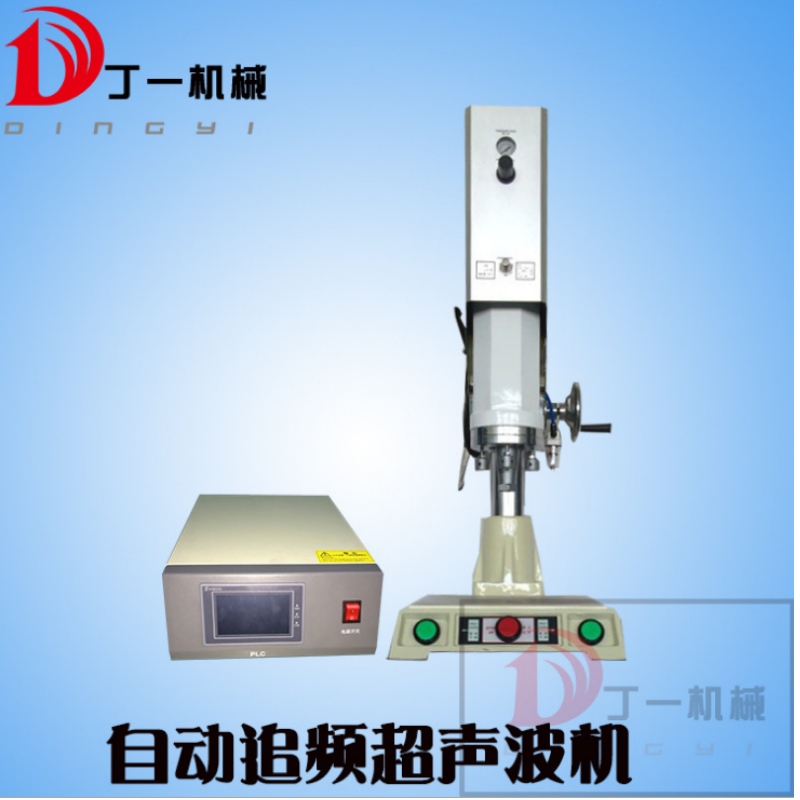

Automatic frequency tracing ultrasonic welding machine